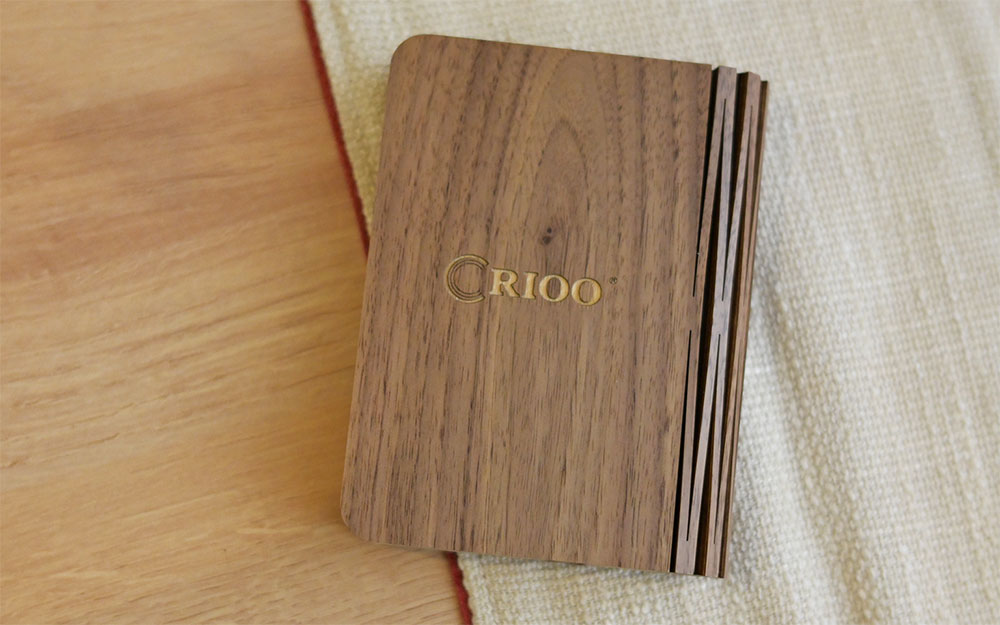

Shell printing process

Material Preparation: Firstly, choose high quality bamboo as the shell material. The bamboo is processed to ensure that the surface is smooth and even and meets the standard suitable for printing.

Surface treatment: Before printing, the surface of bamboo may need to be primed to ensure that the ink adheres better, and at the same time to enhance the clarity and color expression of the pattern.

attern design: According to the demand of the product, the pattern is designed to fit the theme. Patterns are usually drawn with computer design software and then converted into a file format suitable for printing.

Printing technology: UV flatbed printing technology or laser engraving technology is used to print or engrave the pattern directly on the surface of the bamboo; UV flatbed printing can accurately reproduce the details and colors, and is wear-resistant and durable; laser engraving can give the pattern a certain three-dimensional sense and texture.

Protective layer treatment: After the printing or engraving is completed, a layer of transparent protective lacquer is usually added to the surface of the bamboo to enhance wear resistance and waterproof performance, and prolong the service life.

Inside page printing process

Material Preparation: The inner page is made of DuPont paper, which has the characteristics of high strength, tear-resistant and waterproof, and is very suitable for the inner page of the lamps and lanterns.

Pattern design: According to the design theme of the product, design a pattern suitable for printing on DuPont paper. It should be noted that the characteristics of DuPont paper require the design of the pattern to take into account the light transmittance and texture effect of the material.

Shell Carving Process